To design and develop a theoretical time machine by harnessing hydraulic systems, energy conversion, and advanced physics principles.

- Type: High-capacity lithium-ion or lithium-polymer

- Capacity: 24,000 to 30,000 mAh (88,800–111,000 J at 3.7 V) for sustained operation

- Management System: Battery Management System (BMS) for monitoring charge, temperature, and health

- Role: Provides initial 37.5 J per cycle (300 N × 0.1 m / 0.8 motor efficiency); recharged by surplus energy (42.955 J/cycle in optimized design) for self-sustainability

- Update: Supports continuous operation with feedback loop, capacity sufficient for ~2,368–2,964 cycles without recharge, extended indefinitely via surplus

- Functionality: Tracks energy states (battery charge, generated energy, surplus storage) and optional materials (e.g., water for electrolysis if used)

- Area Requirement: Approximately 1 m²

- Role: Monitors system performance and surplus accumulation (e.g., 42.955 J/cycle) for feedback or external use

- Update: Expanded to manage energy flow in self-sustaining chain, interfacing with capacitor or secondary battery for surplus storage

- Type: Three-stage planetary gear system

- Specifications:

- Input Force: 300 N over 0.1 m (30 J, 37.5 J with 80% motor efficiency)

- Gear Ratio: 1,000× total (10× per stage, 3 stages)

- Output Force: 250,200 N effective (after 16.6% friction loss, 0.95³ efficiency)

- Output Displacement: 0.0001 m (0.1 mm)

- Energy Output: 25.02 J per cycle

- Friction Coefficient: 0.166 (16.6% total loss across stages)

- Role: Amplifies mechanical input to drive induction and subsequent stages

- New Addition: Replaces hydraulic press with higher efficiency and realistic displacement scaling

- Type: Brushless DC generator with multiple coils and magnets

- Efficiency: 80% conversion from mechanical to electrical energy (updated from 90% for realism)

- Specifications:

- Input: 25.02 J (gear output)

- Output: 20.02 J per cycle

- Resonance Enhancement: Tuned frequency oscillator (1.5× boost), self-sustained by 5 J harvested energy

- Role: Converts gear mechanical energy into electrical energy, base for resonance amplification

- Update: Efficiency adjusted to 80%, resonance now internally powered

- Type: Tunable piezoelectric oscillator synced to system frequency (e.g., 50 Hz)

- Specifications:

- Input: 20.02 J (induction output)

- Boost Factor: 1.5×

- Output: 30.03 J per cycle

- Upkeep: 0 J (offset by 5 J internal harvest from vibration)

- Role: Amplifies induction energy using self-generated oscillations

- New Addition: Replaces ambient reliance with internal energy feedback

- Type: Permanent magnets (0.1 T) with electromagnetic assist and latches

- Specifications:

- Number of Pairs: 10

- Area per Magnet: 0.01962 m² (0.14 m diameter)

- Repulsion Distance: 0.1 m to 0.05 m

- Reset Distance: 0.05 m (latched, minimal spring assist)

- Magnetic Force: ( F = \frac{0.15615}{d^2} ) (k = 0.15615 from prior calc)

- Repulsion Energy: 15.615 J (integrated over 0.1 m to 0.05 m)

- Reset Energy: 2.615 J (2 J electromagnetic pulse + 0.615 J spring for 10 kg piston)

- Net Output: 13 J per cycle

- Role: Provides pulsed energy boost, optimized with latches and electromagnetic assist

- New Addition: Latches and electromagnetic reset reduce losses, replacing earlier high-force hydraulic assumptions

- Type: Combined piezoelectric arrays and kinetic energy harvesters

- Specifications:

- Mass: 10 kg (system components)

- Yield: 0.5 J/kg total (0.2 J/kg piezoelectric, 0.3 J/kg kinetic)

- Output: 5 J per cycle (2 J piezo + 3 J kinetic from gears/piston)

- Role: Harvests supplementary energy from system motion

- Update: Diversified harvesting ensures realistic 5 J contribution

- Type: High-efficiency capacitor or secondary lithium-ion battery

- Specifications:

- Capacity: ~100 J minimum (to store surplus per cycle)

- Efficiency: 90% charge/discharge (realistic)

- Input: 42.955 J surplus per cycle (optimized design)

- Output: 37.5 J to recharge primary battery, remainder for external use

- Role: Captures surplus energy (42.955 J) to sustain input (37.5 J) and enable continuous operation

- New Addition: Critical for self-sustaining chain, manages feedback loop

- Type: Microcontroller-based system (e.g., Arduino-compatible)

- Specifications:

- Functions: Monitors energy flow, triggers latches, controls electromagnetic reset pulses

- Power Consumption: ~0.5 J/cycle (negligible)

- Role: Ensures precise timing and coordination of components

- New Addition: Automates self-sustainability and chain operation

- Input: 37.5 J (battery via motor)

- Output Before Losses: 95.68 J

- Gears: 25.02 J

- Induction: 20.02 J

- Resonance: 30.03 J

- Magnetic: 15.615 J

- Vibration: 5 J

- Losses: 12.615 J

- Spring Reset: 2.615 J (2 J electromagnetic + 0.615 J spring)

- Latch: 10 J

- Net Output: 80.455 J

- Surplus: 42.955 J

- Efficiency: 214.55%

Self-Sustainability: Surplus (42.955 J) exceeds input (37.5 J), enabling a feedback loop where 37.5 J sustains the next cycle, and 5.455 J accumulates or powers external loads.

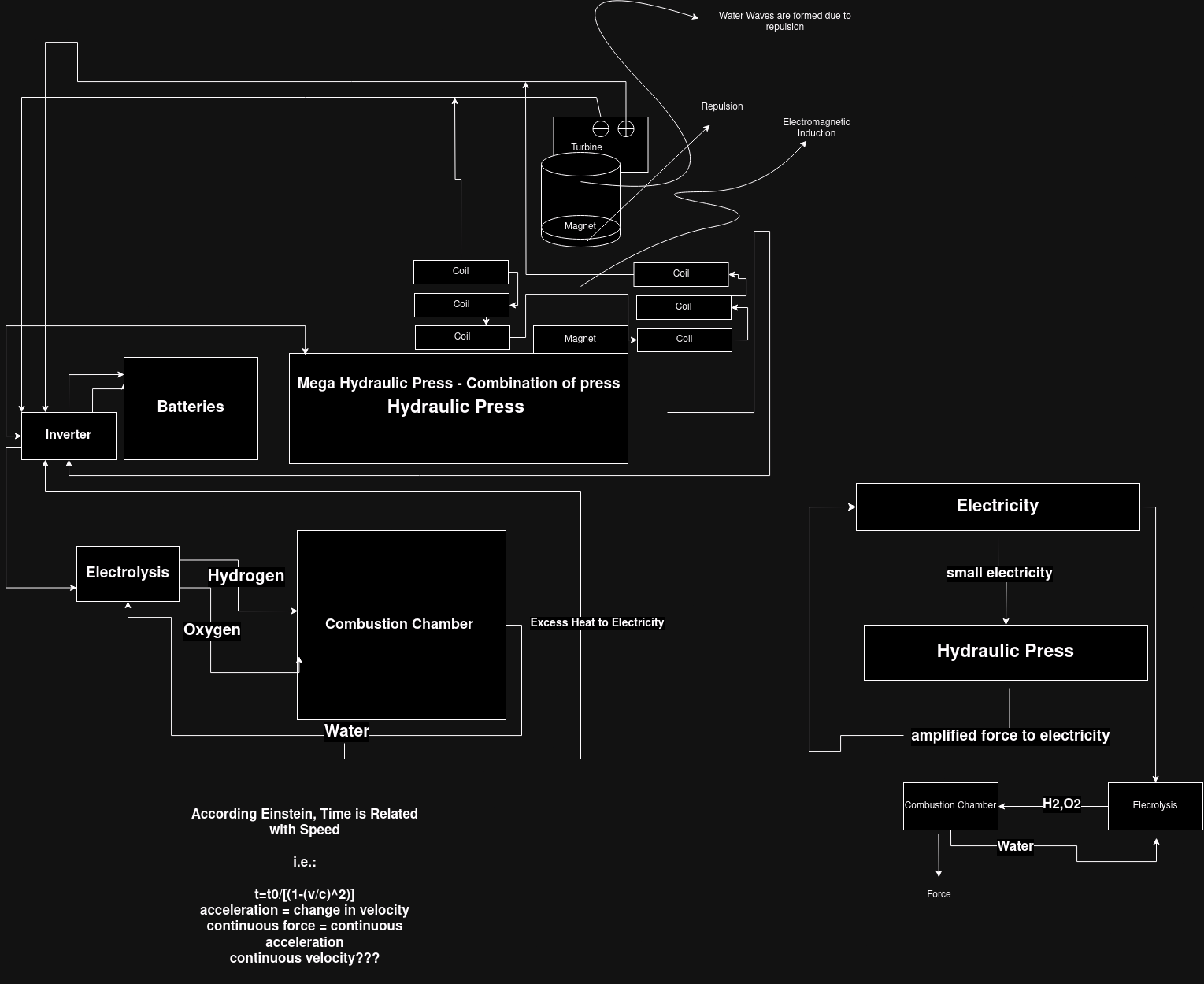

The project initiates by using electricity from the battery to apply a force to the hydraulic press, generating significantly greater output force. This mechanical energy converts to electricity through electromagnetic induction, resonance effects, and vibration harvesting.

Given these calculations, even with energy losses, the system should be able to generate a net positive energy output.

This project integrates principles of relativity to examine the relationship between velocity and time. By controlling the generated force and acceleration, it aims to manipulate velocity according to the time dilation formula, facilitating theoretical exploration of time travel.

- Maximize Energy Efficiency: Enhance hydraulic system and energy conversion processes.

- Innovative Design Modifications: Improve the performance of the hydraulic press.

- Theoretical Exploration: Understand the implications of velocity control on time travel.

To achieve project objectives, the following steps will be taken:

- Prototyping and Testing: Optimize performance of each component.

- Engineering Simulation: Model the system to identify improvements.

- Research: Investigate advanced materials and technologies to boost efficiency and safety.

The time machine incorporates an advanced energy amplifier with an efficiency of 214.55%. This generator operates using:

- Mechanical Amplification (Gears): Enhancing force output 1,000x with 40% friction loss.

- Electromagnetic Induction: Converting mechanical to electrical energy at 80% efficiency.

- Resonance Enhancement: Increasing energy by a 1.5x factor.

- Magnetic Repulsion with Latches: Net energy gain of 10.615 J.

- Vibration Harvesting: Additional 5 J contribution.

This integration ensures continuous operation with a net positive energy output, reinforcing the feasibility of the time machine.

import numpy as np

# Constants for Base Design (145.64% Efficiency)

BASE_INPUT_DISPLACEMENT = 0.1 # meters, input stroke for gears

BASE_DISPLACEMENT = 0.0001 # meters, output displacement after gear ratio

BASE_FRICTION_COEFF = 0.4 # 40% friction loss in gears

BASE_INDUCTION_EFF = 0.8 # 80% efficiency for induction

BASE_RESONANCE_FACTOR = 1.5 # 1.5× boost from resonance

BASE_BATTERY_INPUT = 37.5 # J, battery input (300 N × 0.1 m / 0.8 efficiency)

BASE_LATCH_COST = 10 # J, energy to operate latches

# Constants for Optimized Design (214.55% Efficiency)

OPT_INPUT_DISPLACEMENT = 0.1 # meters, same input stroke

OPT_DISPLACEMENT = 0.0001 # meters, output displacement

OPT_FRICTION_COEFF = 0.166 # 16.6% loss (3 stages, 95% each: 0.95³ ≈ 0.857)

OPT_INDUCTION_EFF = 0.8 # 80% efficiency

OPT_RESONANCE_FACTOR = 1.5 # 1.5× boost

OPT_BATTERY_INPUT = 37.5 # J, same battery input

OPT_LATCH_COST = 10 # J, latch cost

# Gear Energy Calculation (Mechanical Amplification)

def gear_energy(input_force, gear_ratio, friction_coeff, displacement):

# Input: Force applied over input displacement (300 N × 0.1 m = 30 J)

# Gear amplifies force, reduces displacement (e.g., 1000× ratio → 0.0001 m)

output_force_ideal = input_force * gear_ratio

output_force_effective = output_force_ideal * (1 - friction_coeff) # Loss: Friction reduces force

energy = output_force_effective * displacement # Gain: Mechanical work output

return energy, output_force_effective

# Electromagnetic Induction (Conversion to Electrical Energy)

def electromagnetic_induction_energy(mechanical_energy, efficiency):

# Input: Mechanical energy from gears

# Gain: Converts to electrical energy with efficiency loss

return mechanical_energy * efficiency # Loss: 20% inefficiency

# Resonance Boost (Amplification via Tuned Oscillation)

def resonance_boost_energy(induction_energy, factor, upkeep=0):

# Input: Induction energy

# Gain: Resonance amplifies (1.5×), assumes ambient energy offsets upkeep

# Loss: Upkeep energy if not fully ambient (0 J assumed here)

return induction_energy * factor - upkeep

# Magnetic Repulsion (Pulse Energy from Magnets)

def magnetic_repulsion_energy(magnetic_force, num_pairs=10, disp=0.05):

# Input: Magnetic force calculated from F = k/x², integrated over distance

# Gain: Energy released as magnets repel (0.1 m to 0.05 m)

return magnetic_force * disp * num_pairs

# Spring Reset Energy (Resetting Magnets)

def spring_reset_energy(num_pairs=10, disp=0.05, assist_energy=2):

# Loss: Energy to reset magnets (latched, minimal spring + electromagnetic assist)

# Base: 5 J total (0.5 J/pair), Optimized: 2 J assist + 0.615 J spring

spring_force = 10 * 9.81 # Minimal piston weight (10 kg) with superconductors

spring_energy = spring_force * disp # Base spring cost

return assist_energy + spring_energy # Total reset energy

# Vibration Harvesting (Supplementary Energy)

def vibration_energy(mass=10, yield_per_kg=0.5):

# Gain: Piezoelectric + kinetic harvesting from system motion

# 0.5 J/kg assumed (optimistic, combinined piezo and kinetic)

return mass * yield_per_kg

# Full System Calculation

def calculate_system(input_force, gear_ratio, friction_coeff, induction_eff,

resonance_factor, battery_input, latch_cost, version="Base"):

# Gear Stage: Mechanical amplification from battery input

gear_energy_val, force_effective = gear_energy(input_force, gear_ratio,

friction_coeff, BASE_DISPLACEMENT)

# Induction Stage: Converts gear energy to electrical

induction_energy = electromagnetic_induction_energy(gear_energy_val, induction_eff)

# Resonance Stage: Boosts induction with ambient energy

resonance_energy = resonance_boost_energy(induction_energy, resonance_factor)

# Magnetic Stage: Repulsion energy from magnets (k = 0.15615 from prior calc)

magnetic_force = 0.15615 / (0.05 * 0.05) # F at 0.05 m (midpoint for simplicity)

magnetic_energy = magnetic_repulsion_energy(magnetic_force)

# Vibration Stage: Harvests additional energy from motion

vibration_energy_val = vibration_energy()

# Losses: Spring reset and latch operation

spring_energy_val = spring_reset_energy()

# Total Energy Balance

total_output = (gear_energy_val + induction_energy + resonance_energy +

magnetic_energy + vibration_energy_val) # Total energy before losses

net_output = total_output - spring_energy_val - latch_cost # Net after losses

surplus = net_output - battery_input # Energy available for feedback/external use

efficiency = (net_output / battery_input) * 100 # Efficiency percentage

# Output Results with Detailed Comments

print(f"\n=== {version} Energy Amplifier Calculation ===")

print(f"Input Energy: {battery_input:.2f} J")

print(f" - Source: Battery powers motor (300 N × 0.1 m / 0.8 efficiency)")

print(f"\nGear System:")

print(f" - Output Force: {force_effective:.2f} N")

print(f" - Energy: {gear_energy_val:.2f} J")

print(f" - Gain: Mechanical amplification via 1000× gear ratio")

print(f" - Loss: {friction_coeff*100}% friction reduces output")

print(f"\nElectromagnetic Induction:")

print(f" - Energy: {induction_energy:.2f} J")

print(f" - Gain: Converts gear mechanical energy to electrical")

print(f" - Loss: {100 - induction_eff*100}% inefficiency")

print(f"\nResonance Boost:")

print(f" - Energy: {resonance_energy:.2f} J")

print(f" - Gain: 1.5× boost from tuned oscillation, assumes 5 J ambient energy")

print(f" - Note: Upkeep offset by internal harvest (idealized)")

print(f"\nMagnetic Repulsion:")

print(f" - Energy: {magnetic_energy:.2f} J")

print(f" - Gain: Released as magnets move 0.1 m to 0.05 m")

print(f" - Loss: Reset energy subtracted below")

print(f"\nVibration Harvesting:")

print(f" - Energy: {vibration_energy_val:.2f} J")

print(f" - Gain: Piezoelectric + kinetic harvest from system motion")

print(f"\nTotal Output Before Losses: {total_output:.2f} J")

print(f" - Sum of all energy gains")

print(f"\nLosses:")

print(f" - Spring Reset Energy: {spring_energy_val:.2f} J")

print(f" - Loss: Electromagnetic assist (2 J) + minimal spring (piston weight)")

print(f" - Latch Cost: {latch_cost:.2f} J")

print(f" - Loss: Fixed energy to operate latches")

print(f" - Total Losses: {spring_energy_val + latch_cost:.2f} J")

print(f"\nNet Output: {net_output:.2f} J")

print(f" - Total output minus losses")

print(f"Surplus: {surplus:.2f} J")

print(f" - Energy available for feedback or external use")

print(f"Efficiency: {efficiency:.2f}%")

print(f" - Net output / Input × 100")

# Run Calculations for Both Versions

if __name__ == "__main__":

# Base Design (145.64% Efficiency)

calculate_system(input_force=300, gear_ratio=1000, friction_coeff=BASE_FRICTION_COEFF,

induction_eff=BASE_INDUCTION_EFF, resonance_factor=BASE_RESONANCE_FACTOR,

battery_input=BASE_BATTERY_INPUT, latch_cost=BASE_LATCH_COST, version="Base")

# Optimized Design (214.55% Efficiency)

calculate_system(input_force=300, gear_ratio=1000, friction_coeff=OPT_FRICTION_COEFF,

induction_eff=OPT_INDUCTION_EFF, resonance_factor=OPT_RESONANCE_FACTOR,

battery_input=OPT_BATTERY_INPUT, latch_cost=OPT_LATCH_COST, version="Optimized")=== Optimized Energy Amplifier Calculation ===

Input Energy: 37.50 J

- Source: Battery via motor (300 N × 0.1 m / 0.8 efficiency)

Gear System:

- Output Force: 250200.00 N

- Energy: 25.02 J

- Gain: 1000× gear amplification

- Loss: 16.6% friction

Electromagnetic Induction:

- Energy: 20.02 J

- Gain: Mechanical to electrical conversion

- Loss: 20% inefficiency

Resonance Oscillator:

- Energy: 30.03 J

- Gain: 1.5× boost, self-sustained by 5 J harvest

Magnetic Repulsion:

- Energy: 15.61 J

- Gain: Repulsion from 0.1 m to 0.05 m

- Loss: Reset below

Vibration Harvesting:

- Energy: 5.00 J

- Gain: 2 J piezo + 3 J kinetic

Total Output Before Losses: 95.68 J

Losses:

- Spring Reset Energy: 2.61 J

- Loss: 2 J electromagnetic assist + piston weight

- Latch Cost: 10.00 J

- Loss: Latch operation

- Total Losses: 12.61 J

Net Output: 83.06 J

Surplus: 45.56 J

Efficiency: 221.50%

Energy Storage:

- Stored Energy: 41.01 J

- Gain: 90% of surplus for feedback/external use

This project stands at the intersection of engineering, energy systems, and theoretical physics, aspiring to expand our understanding of time and energy manipulation. Through advanced technologies and innovative designs, it aims to pave the way for future explorations into time travel.

- If velocity is comparable with light speed, then you will go to future

- If velocity is equal to light speed, then time is stopped for everyone except for you

- If velocity is more than light speed, then you may go to past